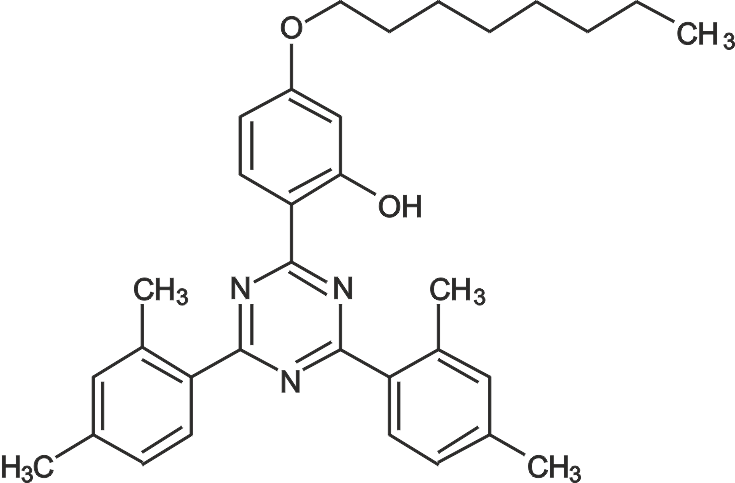

| 1. STRUCTURE | |

|---|---|

|

| 2. PRODUCT NAME & DETAILS | |

|---|---|

| Product Name | 2,4-Bis(2,4-dimethylphenyl)-6-(2-hydroxy-4-octyloxyphenyl)-1,3,5-triazine (Appolo-1164 (M)) |

| Product Code | 010631 |

| CAS No | 2725-22-6 |

| HS Code | 2933.69.90 |

| Molecular Formula | C33H39N3O2 |

| Molecular Wt. | 509.68 |

3. ADDITIONAL ADVANTAGES | - Particle size is less than 800 Micron (90%). - Increasing surface area.- Allows faster chemical reaction times. - Improved performance of final product. - Accelerate in rate of dissolution. - UV radiation absorption increases with smaller particles | ||

| 4. REGULATORY INFORMATION | |||

| Chemical name | Common names and synonyms | CAS number | EC number |

| 2,4-Bis(2,4-dimethylphenyl) -6-(2-hydroxy-4-n-octyloxyphenyl) -1,3,5-triazine | 2,4-Bis(2,4-dimethylphenyl) -6-(2-hydroxy-4-n-octyloxyphenyl) -1,3,5-triazine | 2725-22-6 | 412-440-4 |

| European Inventory of Existing Commercial Chemical Substances (EINECS) | Not Listed | ||

| EC Inventory | Listed | ||

| United States Toxic Substances Control Act (TSCA) Inventory | Listed | ||

| China Catalog of Hazardous chemicals 2015 | Not Listed | ||

| Chinese Chemical Inventory of Existing Chemical Substances (China IECSC) | Listed | ||

| Korea Existing Chemicals List (KECL) | Listed | ||

| Canadian Domestic Substance List (DSL) | Listed | ||

| Canadian Non-Domestic Substance List (NDSL) | Not Listed | ||

| Japanese Existing and New Chemical Substances Inventory (ENCS) | Listed | ||

| 5. SPECIFICATION | |

| Physical Appearance | Yellowish Fine Powder |

| Identity HPLC | Identical |

| Melting Point | 89.5 to 92.0 °C |

| Loss On Drying | NMT 0.50% |

| Purity By HPLC | NLT 99.0% |

| Transmittance (%) 500 NM | NLT 95.0% |

| Transmittance (%) 460 NM | NLT 90.0% |

| Particle Size | Less Than 800 Micron (90%) |

| Apha Colour | NMT 150 |

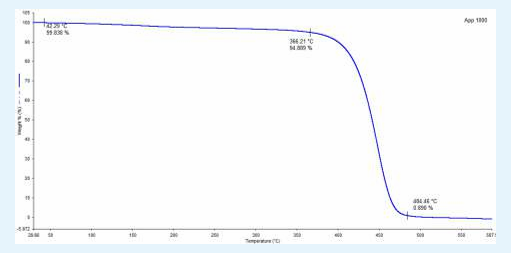

| 6. TGA CURVE |  | ||||||||||||||||||||||||||||||||

| 7. APPLICATION | - UV Absorber 1164 is used as a stabilizer for olefin polymers intended for use in contact with food. - It is also used as UV light absorber and high inherent UV stabilizer in other polymers. Excellent compatibility with other stabilizer chemistries. - Used in products to protect them from long-term degradation from the effects of UV exposure. - Minimal color contribution. It also show Low interaction with metals. - Used in rubber products (e.g. tires) and their manufacture. UV 1164 has a very low volatility. - This product is suitable for polyoxymethylene, polyamide, polycarbonate, polyethylene, polyether amine, ABS resin and polymethyl methacrylate. Especially suitable for nylon and engineering plastics. - Polyethylene sheets used for agriculture/Greenhouse films, PPE in hospitals and in medical devices such as incubation tubs. | ||||||||||||||||||||||||||||||||

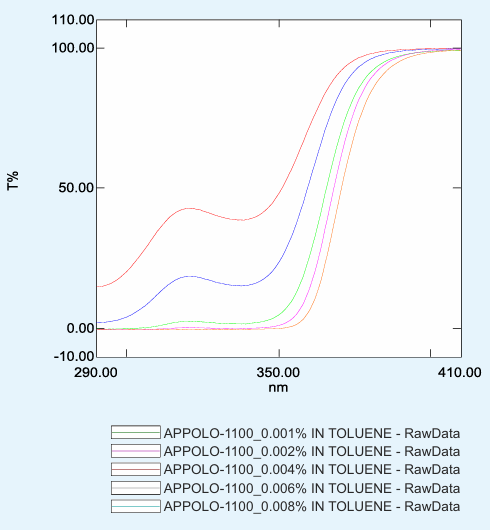

| 8. APPOLO-1164 (M) : SPECTRAL TRANSMISSION |  | ||||||||||||||||||||||||||||||||

| 9. Food Approval status (for plastic coming in contact with food) CAS No.2725-22-6 has EU & FDA approval. In USA according to FDA 21 CFR part section 178.2010 | A. At levels not to exceed 0.3 percent by weight of olefin polymers complying with 177.1520(c) of this chapter in contact with food types I, II, IV-B, VI, VII-B, and VIII described in 176.170(c) of this chapter, table 1, under conditions of use D through G as described in 176.170(c), table 2, of this chapter. B. At levels not to exceed 0.1 percent by weight of polypropylene complying with 177.1520(c) of this chapter, items 1.1a, 1.2, and 1.3 in contact with food under conditions of use A through H as described in 176.170(c), table 2, of this chapter. C. At levels not to exceed 0.04 percent by weight of polyethylene and olefin copolymers complying with 177.1520(c) of this chapter, items 2.1, 2.2, 2.3, 3.1a, 3.1b, 3.1c, 3.2a, and 3.2b having a minimum density of 0.94 gram per cubic centimeter, in contact with food under conditions of use A through H as described in 176.170, table 2, of this chapter provided that the finished articles used in contact with fatty food types III, IV-A, V, VII-A, and IX as described in table 1 of 176.170(c) of this chapter hold a minimum of 2 gallons (7.6 liters) of food. D. At levels not to exceed 0.4 percent by weight of ethylene copolymers complying with 177.1520(c) of this chapter, items 3.1a, 3.1b, 3.1c, 3.2a, and 3.2b, having a density of less than 0.94 gram per cubic centimeter, in contact with food under conditions of use B through H, as described in 176.170(c), table 2, of this chapter provided that the finished articles used in contact with fatty food types III, IV-A, V, VII-A, and IX hold a minimum of 5 gallons (18.9 liters) of food. E. At levels not to exceed 0.04 percent by weight of polyethylene having a density of less than 0.94 gram per cubic centimeter, and olefin polymers complying with 177.1520(c) of this chapter, items 2.1, 2.2, 2.3, 3.3a, 3.3b, 3.4, 3.5, 3.6, 4, 5, and 6, in contact with food under conditions of use D through G as described in 176.170(c) of this chapter, table 2, provided that the finished articles used in contact with fatty food types III, IV-A, V, VII-A, and IX hold a minimum of 5 gallons (18.9 liters) of food. F. EU Approval : Appolo-1164 with CAS no. 2725-22-6 is registered under Ref. no. 38885 and has a SML=5 mg/kg. | ||||||||||||||||||||||||||||||||

| 10. HAZARD CLASSIFICATION | Non Hazardous material. | ||||||||||||||||||||||||||||||||

| 11.DUST EXPLOSION HAZARD | DUST EXPLOSION TEST (MODIFIED HARTMANN APPARATUS): Test Method: FTL/SOP/05, Based on International Test Method: VDI 2263 PART 1/2.1.1; 2003 Description: Sample is dried at 50°C under vacuum, sieved through 63μ sieve. Weighed amount of product is charged into a modified Hartmann tube of 1.2 liter volume. The product is converted into a dust cloud in glass cylindrical tube with compressed air and electrodes with continuous spark is used as ignition source to ignite this dust cloud. Based on dust fire or extent of opening of the hinged cover rating 0, 1 or 2 are assigned. Test is repeated with varied weights of the sample

| ||||||||||||||||||||||||||||||||

| 12. ANNUAL CAPACITY | 50 MT. | ||||||||||||||||||||||||||||||||

| 13. STORAGE CONDITION | Stored in closed container at ambient temperature. Avoid direct sunlight. | ||||||||||||||||||||||||||||||||

| 14. PACKING DETAILS | Big Jumbo Bag Bag Capacity 500 kg and Net Wt. 250 kg 1 Bag of 250 kg on One Pallet Corrugated Boxes (7 Ply) Size = 360 X 360 X 480 mm Net Quantity per box = 15 kgs Inner Packing double plastic liner inside 27 boxes can be placed on wooden pallet (ISPM 15) in 3 tier (9 Boxes in one tier * 3 tier = 27 Boxes) Total quantity per pallet = 27*15 = 405 kgs One 20 feet container load quantity = 405*10 pallets = 4050 kgs | ||||||||||||||||||||||||||||||||

| 13. SHELF LIFE | 3 years. |

| Disclaimer |

|---|

| Typical properties should not be considered as specification. Product covered by valid patents are not offered or supplied for commercial use. The Patent position should be verified by the customer. Products will not be supplied to countries where they could be in conflict with existing patents. Products currently covered by valid US patents are offered for R&D use in accordance with 35 USC 271 (e) (I) Above information is given in good faith and without warrenty. |

The above information is given in good faith and is without warranty